Step-by-Step Guide to Checking HVAC Compressor Power

Getting to Know HVAC Compressors

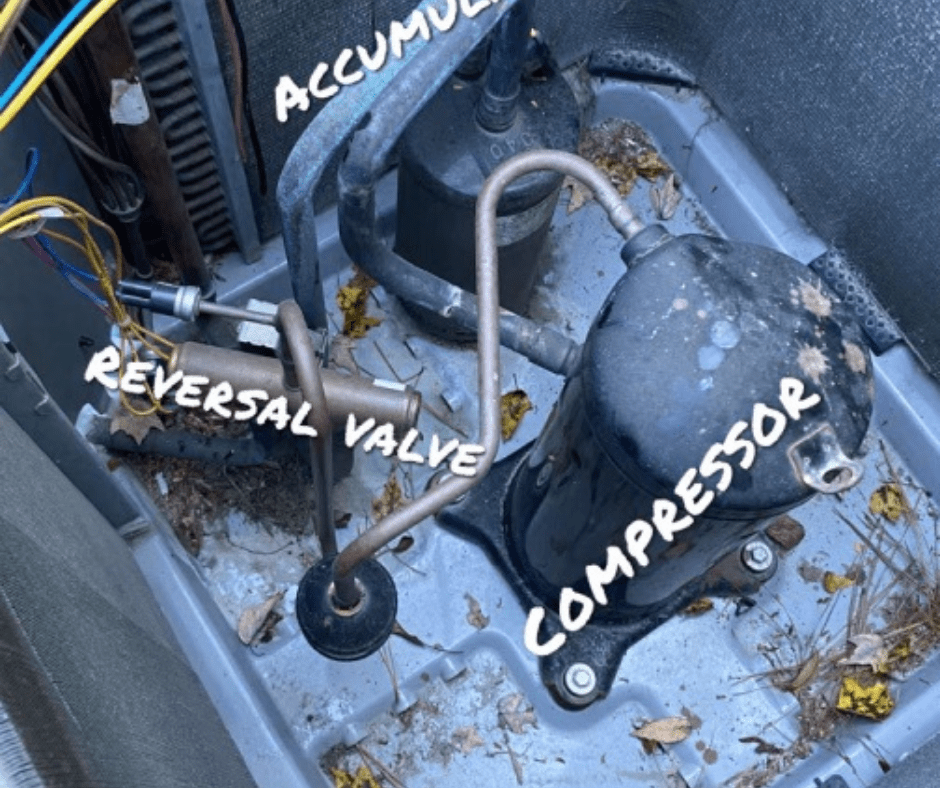

An HVAC compressor is a critical component in your heating and cooling system. Its primary function is to compress the refrigerant, increasing its temperature and pressure, which enables it to circulate efficiently throughout the system. You’ll usually find the compressor housed in the outdoor unit of your HVAC setup. Understanding the role of the compressor is key to diagnosing and fixing any potential heating and air issues.

In essence, the compressor helps in the heat exchange process by moving the refrigerant between the evaporator and condenser coils. When the refrigerant is compressed, it transforms from a low-pressure gas to a high-pressure gas, facilitating effective heat transfer.

Knowing where the compressor fits into the overall HVAC system can help you better understand any issues that might arise and how to approach them. This familiarity will be especially useful when it comes time to inspect the component for power issues or other common problems.

Collecting Required Tools and Safety Equipment

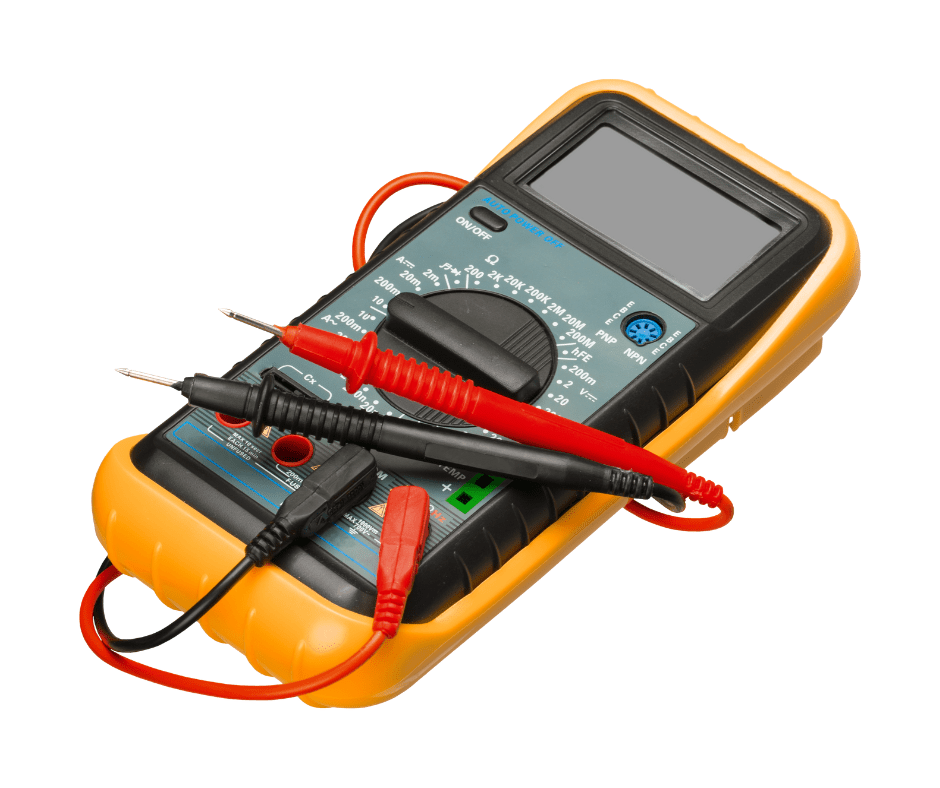

Before diving into the HVAC inspection, gather the essential tools to ensure a smooth process. You’ll need a multimeter to measure electrical values, a set of screwdrivers to remove panels, and insulated gloves to protect yourself from electrical hazards. Safety goggles are also crucial to shield your eyes from any debris or unexpected sparks.

It’s important to understand how to use each tool properly. A multimeter, for instance, is vital for measuring voltage and current accurately, so familiarize yourself with its functions if you haven’t used one before. Insulated gloves will help keep you safe by providing a barrier against potential electric shocks.

Make sure your workspace is clean and well-organized. This reduces the risk of accidents and makes it easier to find your tools when you need them. Additionally, having a flashlight can be helpful if you’re working in dim conditions or need to inspect dark areas of the unit.

By preparing your tools and ensuring you have the right safety equipment, you set the stage for a successful and safe inspection of your HVAC system‘s compressor.

Shutting Down the HVAC System

Begin by ensuring your HVAC system is turned off to maintain a safe working environment during your inspection. Follow these steps to shut down the system:

1. Locate the main power switch or circuit breaker for your HVAC system. This is typically found in your home’s electrical panel or near the HVAC unit.

2. Flip the switch or breaker to the “Off” position, cutting off the power supply to the unit.

3. Allow a few minutes to pass to ensure the HVAC system is completely powered down.

To verify that the heating and air conditioning system is fully off, try turning on the HVAC unit using your thermostat. If it remains unresponsive, you can be confident the power has been successfully cut.

Taking these precautions will ensure you can proceed with your inspection without the risk of electric shock or injury. Always make sure that you have full control over the power supply before working on any electrical components.

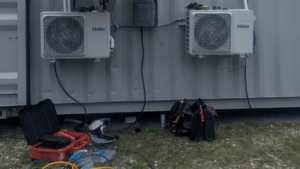

Reaching the HVAC Compressor

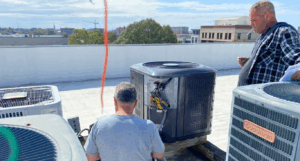

After ensuring your HVAC system is turned off and you have gathered all necessary tools and safety equipment, it’s time to locate and access the compressor. Begin by identifying the outdoor unit, which typically houses the compressor. Using your screwdriver, remove any protective covers or panels carefully. It’s helpful to place screws and small parts in a container to avoid losing them during the process.

Once the protective covers are removed, you should have a clear view of the compressor. Ensure the workspace is free from debris, moisture, and any other obstructions. A clean area reduces the risk of accidental damage or safety hazards while you work. If your working conditions are dim, use a flashlight to improve visibility.

Take a moment to visually inspect the compressor and surrounding components for any signs of damage, wear, or loose parts. Pay particular attention to wiring and connections, as these are common areas where issues may arise. If you notice any frayed or disconnected wires, make a note to address these during your inspection.

Approach the HVAC compressor with care, avoiding rushed movements that might lead to mishaps. Keeping a methodical and patient approach ensures a thorough inspection and helps prevent any unintentional heating and cooling errors.

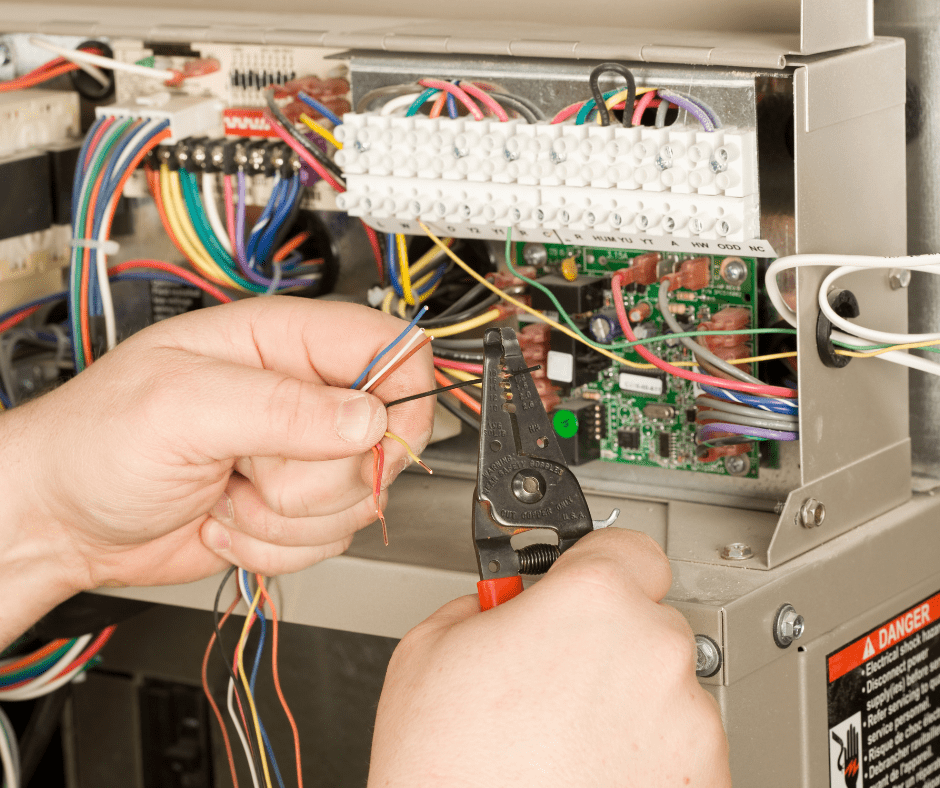

Examining Electrical Connections

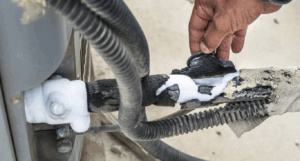

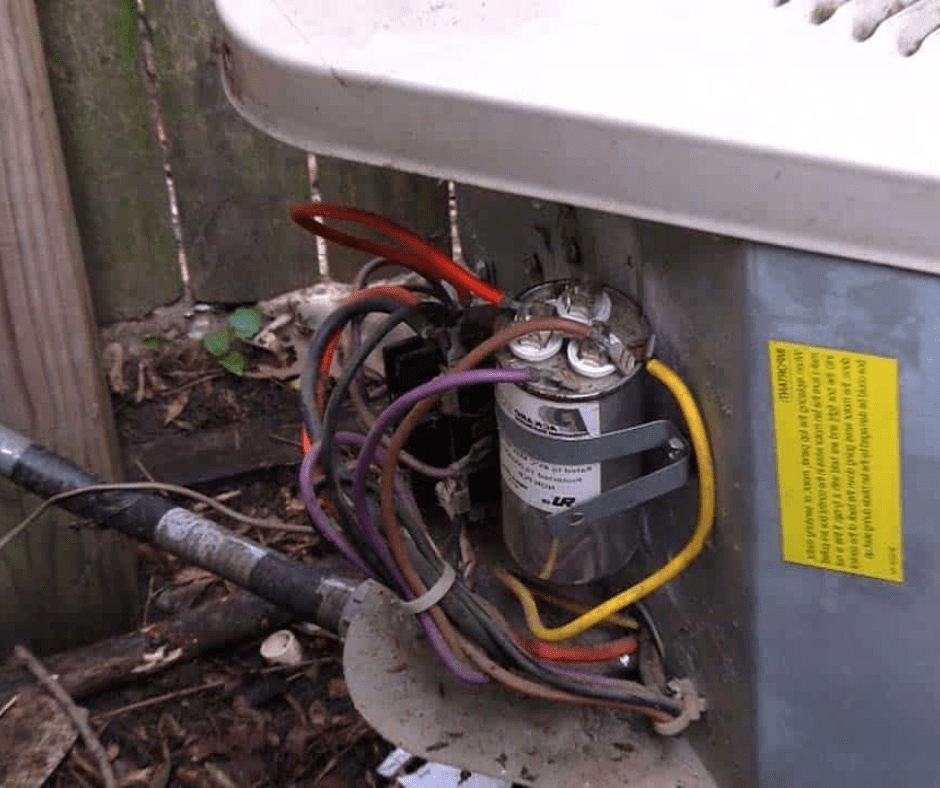

With the HVAC compressor exposed, it’s time to focus on the electrical connections. Start by inspecting all wires visually. Look for any signs of wear and tear, such as frayed or broken wires, which could disrupt the power flow. Check for loose connections by gently tugging on the wires; they should be snug and secure in their terminals.

Next, get your multimeter ready to test for continuity. Set the multimeter to the continuity setting, which is often indicated by a soundwave or diode symbol. Place the probes on either end of each wire or connection point. A steady beep or a reading on the display indicates that the connection is intact.

If you find any damaged HVAC system wires, they need to be repaired or replaced. Use wire strippers to remove any damaged insulation, then twist the exposed wires together and secure them with wire nuts. For loose connections, tighten the screws or terminals to ensure a firm grip.

It’s also important to examine your heating and cooling systems contactor and capacitor, as these components are crucial for the compressor’s operation. Ensure the contactor is free of debris and the capacitor isn’t bulging or leaking, which are signs of failure. By thoroughly inspecting these electrical connections, you help ensure the compressor can function properly and efficiently.

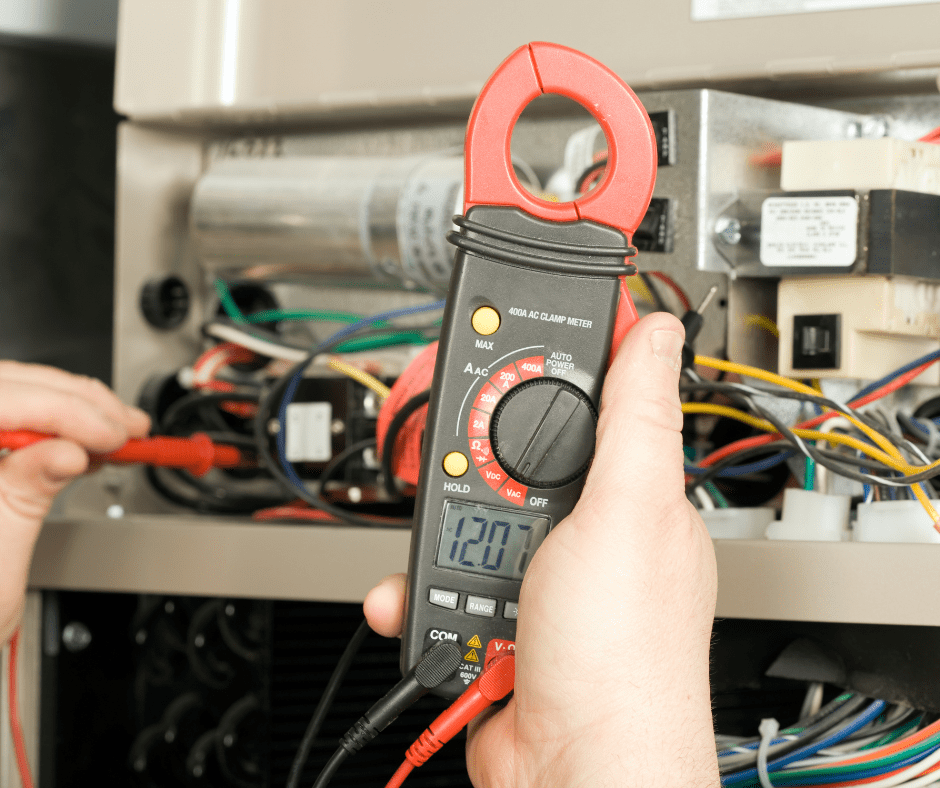

Checking Voltage and Current

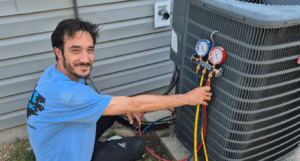

With your multimeter in hand, it’s time to check the voltage and current of your HVAC compressor to ensure everything is functioning as it should. First, set your multimeter to measure AC voltage. Attach the probes to the designated terminals on the compressor, typically labeled for easy identification. Once connected, read the voltage displayed on the multimeter. This reading should align with the manufacturer’s specifications, which can usually be found in the unit’s manual or on a label attached to the HVAC system.

Next, switch your multimeter to the current measurement setting. This step may require clamping around the wire connected to the compressor to read the current flow accurately. Again, compare your findings to the manufacturer’s guidelines. Any discrepancies in these readings could indicate potential issues that need further investigation.

If your voltage or current readings fall outside the specified range, it could signal problems such as an overloaded circuit or an issue within the compressor itself. In such cases, it’s advisable to consult an HVAC professional for a more in-depth diagnosis and repair.

By carefully checking these electrical values, you play a crucial role in maintaining your HVAC system’s performance and preventing unexpected breakdowns. Always refer to your HVAC system’s documentation for the correct specifications and heating and air troubleshooting tips.

Reassembling and Restarting the Unit

Now that you’ve thoroughly inspected the HVAC compressor and addressed any issues, it’s time to put everything back together and restart your HVAC system. Start by reattaching any panels or covers you removed. Be careful to align them correctly and securely fasten all screws, using your screwdriver. Ensuring all components are properly in place helps protect the unit and maintain its efficiency.

Double-check that you haven’t left any tools or debris inside the unit. It’s a good idea to give the area a quick clean to remove any dust or dirt that may have accumulated during the inspection. This helps maintain a tidy and safe work environment.

Once the unit is reassembled, restore power to the HVAC system by turning the circuit breaker or main switch back to the “On” position. Allow a few moments for the system to stabilize and power up.

Next, set your thermostat to the desired temperature and observe the system’s behavior. Listen for any unusual sounds coming from your HVAC system and ensure the compressor activates and runs smoothly. Watch for proper cooling or heating, depending on your settings, to confirm everything is operating correctly.

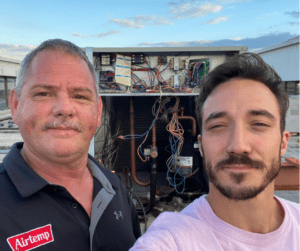

By carefully reassembling the unit and restoring power, you ensure that your HVAC system is ready to provide reliable comfort once again. If any issues arise, don’t hesitate to consult an HVAC professional for further assistance.

Solving Common Problems

During your inspection, you might come across a few common issues that can affect your HVAC compressor’s performance. Loose connections are often a culprit; ensure all wires and terminals are tightly secured to maintain proper electrical flow. If you notice inadequate voltage readings, it may be time to call in a professional HVAC technician to assess your home’s power supply and rectify any issues.

Unusual noises coming from the compressor can also be a sign of trouble. Check for any loose or worn-out parts that may be causing the noise. Sometimes, these sounds indicate a need for professional assessment and repair. Addressing these problems promptly can help maintain the efficiency and longevity of your HVAC system. Regular inspections and timely repairs are key to avoiding larger, more costly issues down the line. If you’re ever unsure about a problem or how to fix it, don’t hesitate to seek professional heating and air conditioning guidance. Your safety and comfort are paramount.

Conclusion

You should now be well equipped with the proper knowledge to change your HVAC compressor for your heating and air conditioning system. If you do not feel comfortable in trying to change the HVAC compressor yourself, we highly recommend you contact a qualified HVAC company in your area. For more heating and air conditioning tips be sure to read our following related articles.